※ Product Introduction:

CS-9804C LED soft light strip silicone is a condensation type room temperature curing silicone sealant, which is a specialized sealant for surface drip LED soft light strips. Compared with epoxy sealant and PU sealant, this series of adhesives has the following significant characteristics:

1. It has excellent waterproof properties, which can protect lighting fixtures from water erosion and prevent fogging when lit in water for a long time;

2. It has excellent heat dissipation, which can ensure that the chip will not affect its service life due to high temperature during use;

3. Having excellent transmittance and refractive index, it can greatly reduce the light attenuation of the light source;

4. Having super strong UV resistance, it can ensure that the lighting fixtures are used outdoors for a long time;

5. It has excellent weather resistance and can ensure the normal use of lighting fixtures in a wide temperature range (-40~220 ℃) and special environments such as underwater, making the use of lighting fixtures almost unlimited in geographical areas;

6. This series of products belongs to room temperature curing type, and its main curing mechanism is to react with moisture in the air to cure, so it is not sensitive to temperature, making its curing conditions simpler and operation easier.

※ Usage and precautions

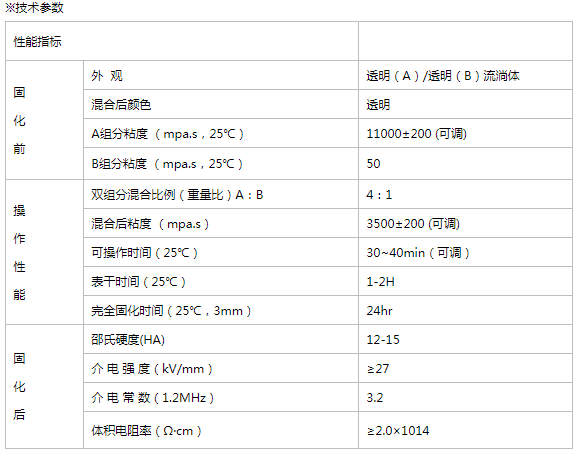

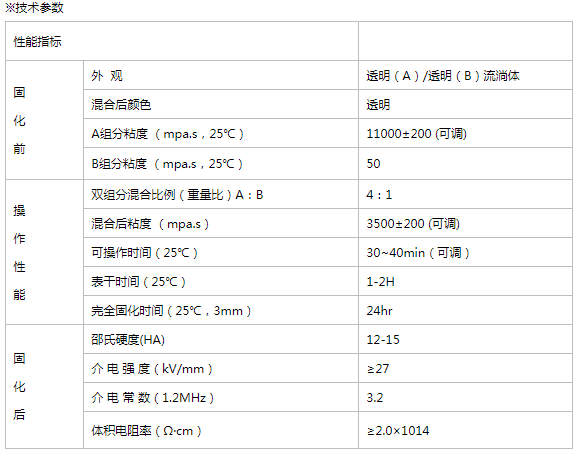

1. Mix the adhesive of components A and B evenly in a weight ratio of 4:1; (When mixing glue, it is important to ensure that no other impurities are introduced, and it is best to use clean specialized containers and mixing rods);

2. Put the mixed glue into the defoaming device for defoaming, and seal it after the bubbles are completely removed; Due to the low surface tension of silicone gel, it is easy for the gel to overflow from the container during the defoaming process. Therefore, it is best to use a container with four times the volume of the gel or to use the intermittent defoaming method for defoaming. That is, after the bubbles accumulate in a vacuum state for 10 seconds, quickly turn off the vacuum machine to restore normal pressure. After repeating this process several times, the bubbles can be emptied and the gel will not overflow from the container;

3. Transfer the defoamed glue into a dedicated glue container or equipment for sealing; (This adhesive will shrink in volume during the curing process, so try to fill it as fully as possible when sealing, as it will be more aesthetically pleasing after curing);

4. After 1-2 hours of gel surface drying (non stick surface), the light strip can be removed from the operating platform for subsequent operations;

※ Special Reminder

1. This adhesive cannot be mixed with other adhesives;

2. When mixing two components, efforts should be made to ensure even mixing;

3. If conditions permit, the mixed adhesive should be treated with defoaming as much as possible;

4. The prepared glue must be used up within the operable time to avoid unnecessary waste;

5. When using as surface glue drops, it is recommended that the customer can configure the glue drops for the second time after the first time of dripping and after its gel, so that the appearance will be better after curing.

6. Therefore, the series of adhesives will react when they come into contact with water, and any unused adhesive must be sealed and stored. The best storage conditions are at room temperature and in a cool place.

7. This product should be avoided from long-term contact with organic solvents such as washing water and thinner, as well as strong acids and bases.

8. Due to the materials and processes used by different customers being beyond the control of our company, it is necessary to conduct compatibility tests and samples before using this adhesive. After the samples are qualified, you can use them with confidence.

Mobile website

Mobile website WeChat official account

WeChat official account