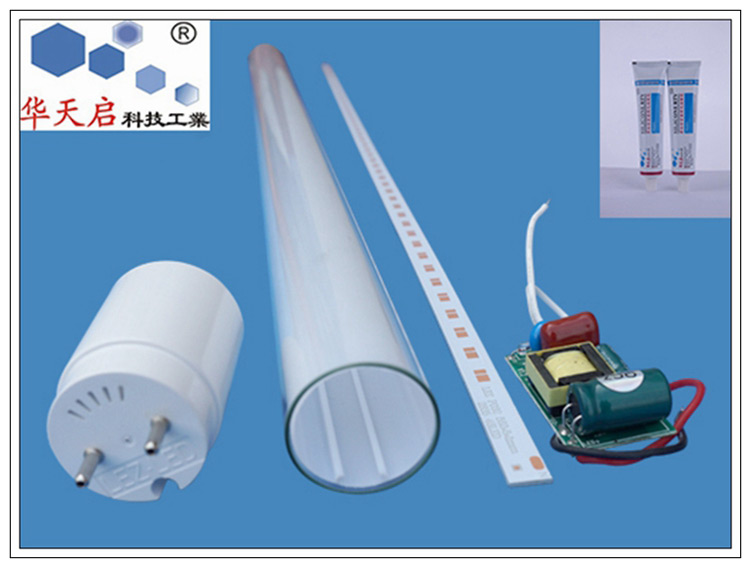

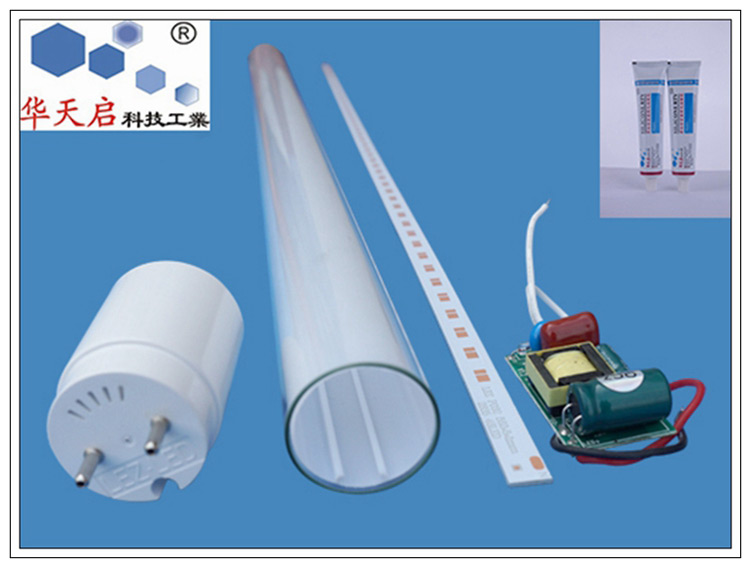

Mainly used for surface coating, fixing, shock absorption, etc. of precision electronic components, inductors and coils in module power supplies. Such as switch power supplies, transformers, power modules, network transformers, etc.

Clean the construction surface thoroughly, cut off the top of the nozzle according to the amount used, seal it on the packaging mouth, apply it to the construction surface, and place it in the air. The surface of this product will lose its stickiness (surface dryness) after 3-8 minutes at room temperature, and it will completely cure within 8-24 hours. Heating this product cannot significantly change its curing speed.

Unused adhesive should be stored in a sealed container. The storage period is 6 months (25 ℃).

This product is non hazardous, but should not be ingested or seen.

Transportation: There are no regulations for domestic (CN-GB) or international (IMO, IATA, UN) transportation. Belonging to non dangerous goods.

performance index

Before curing: ① Appearance: semi transparent and semi flowing ② Product type: condensation type ③ Viscosity (mpa. s, 25 ℃): 40000-70000 ④ Relative specific gravity (25 ℃): 1.1 ± 0.05

Operational performance: ① Surface skinning time (min, 25 ℃): 3-8 ② Curing time (min, 25 ℃): 8-12 hours (3-5mm) ③ Curing time (min, 80 ℃)

After curing: ① Hardness (shore A): 25-35 ② Thermal conductivity [W (m · K)] ③ Dielectric strength (kV/mm): ≥ 15 ④ Dielectric constant (100MHz): 3.0

⑤ Volume resistivity (Ω· cm): ≥ 1.0 × 1015 ⑥ Tensile elongation at break (%): 120-150 ⑦ Operating temperature range (℃): -60 ℃ -200 ℃ ⑧ Flame retardant grade

The above mechanical and electrical performance data were measured after 7 days of curing at 25 ℃ and 75% relative humidity.

CS-862 single component room temperature cured silicone rubber has the following characteristics:

This product is a single component organic silicon compound, with a semi transparent and semi flowing color.

This product has good high and low temperature resistance, earthquake resistance, corona resistance, anti leakage insulation, corrosion resistance, weather resistance and other characteristics. After solidification, the colloid can be used within a wide temperature range (-50~200 ℃).

During the curing process, it does not shrink and has good waterproof, moisture-proof, and insulating properties.

Compliant with the EU ROHS directive requirements.

Mobile website

Mobile website WeChat official account

WeChat official account