It is mainly composed of adhesive and thermal conductive particles. Before gluing, it is a paste like mixture, and after gluing, it solidifies under certain time and conditions. Our thermal conductive silicone is a single component room temperature vulcanized silicone rubber with good adhesive properties. Room temperature curing The curing conditions are simple Repackable, with a curing thickness generally between 4-5mm. But it is sensitive to the surface state of the heat sink, and the bonding strength of devices or heat sinks with surface contamination is weak. Strict on-site process control.

1. Environmentally friendly, non-toxic, non corrosive, in compliance with ROHS and REACH directives.

2. Excellent adhesion, fixation, insulation, sealing, moisture resistance, shock resistance, and aging resistance.

3. It can firmly adhere to different materials such as metal, glass, ceramics, plastics, etc.

4. The cured silicone rubber has good electrical insulation performance, high and low temperature resistance, waterproof and moisture-proof, aging resistance, and long-term rubber elasticity.

performance index

Before curing: ① Appearance: white paste ② Product type: condensation type ③ Viscosity (mpa. s, 25 ℃): 30000-50000 ④ Relative specific gravity (25 ℃): 1.55 ± 0.05

Operational performance: ① Surface skinning time (min, 25 ℃): 3-8 ② Curing time (min, 25 ℃): 8-12 hours (3-5mm) ③ Curing time (min, 80 ℃)

After curing: ① Hardness (shore A): 35-45 ② Dielectric strength (kV/mm): ≥ 15 ③ Dielectric constant (100MHz): 3.5

④ Volume resistivity (Ω· cm): ≥ 1.0 × 1014 ⑤ Elongation at break (%): 160-200 ⑥ Tangent value of dielectric loss (1MHz): ≤ 2.0 × 10-3

⑦ Temperature range for use (℃): -50 ℃ -180 ℃ ⑧ Flame retardant grade: 94V0

The above mechanical and electrical performance data were measured after 7 days of curing at 25 ℃ and 75% relative humidity.

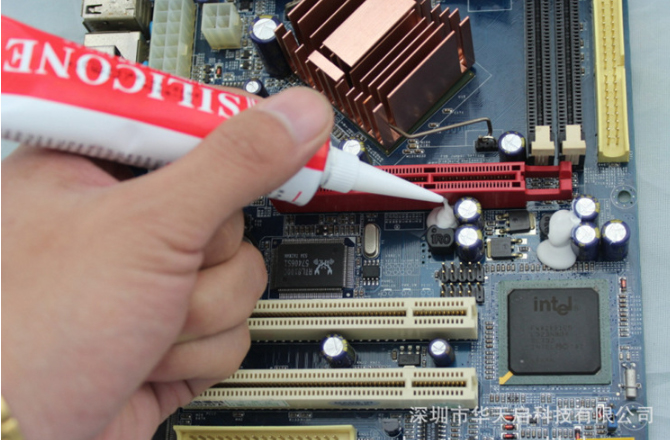

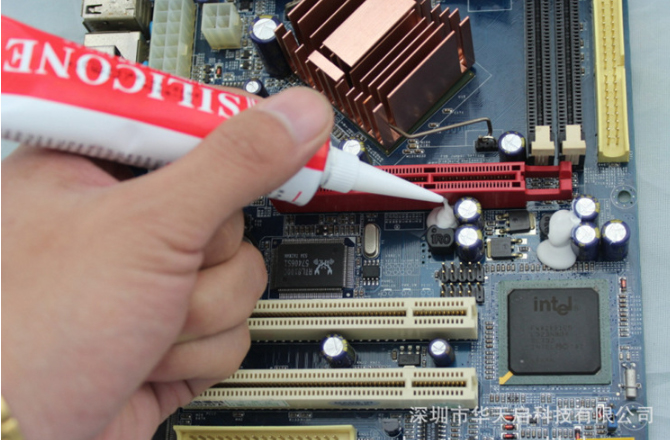

Mainly used for fixing electronic and electrical components, shock absorption, bonding, insulation and other functions. Such as switch power supplies, lighting fixtures, transformers, circuit boards, network transformers, etc.

characteristic:

This product is a single component organic silicon compound in the form of a white paste.

This product has good high and low temperature resistance, earthquake resistance, corona resistance, anti leakage insulation, corrosion resistance, weather resistance and other characteristics. After solidification, the colloid can be used over a wide temperature range.

During the curing process, it does not shrink and has good waterproof, moisture-proof, and insulating properties.

Compliant with the EU ROHS directive requirements.

Mobile website

Mobile website WeChat official account

WeChat official account