1、 Product Introduction:

After curing, polyurethane sealant is mostly soft and elastic, which can be repaired. It has good flexibility and impact resistance, and can quickly recover after deformation. It is a sealing adhesive between epoxy resin adhesive and silicone. It has the characteristics of low hardness, moderate strength, waterproof and moisture-proof, and shock resistance. It can be cured at room temperature or by heating, and can be deeply cured. The two-component mixture has good flowability and excellent flexibility after curing.

usage method:

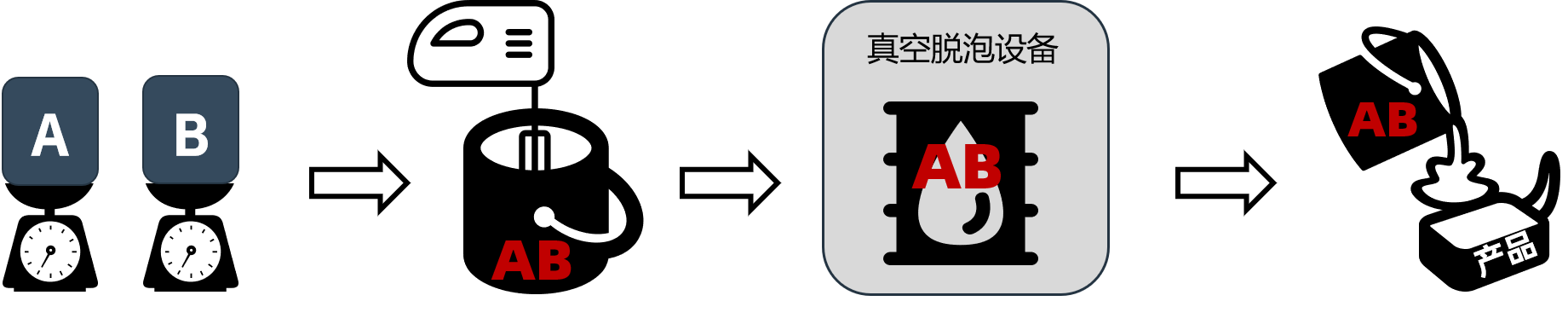

Recommended manual gluing process

Preheating: When the temperature is low, the viscosity of component A will increase, and component B is prone to crystallization. Please preheat the material to 25-45 ℃ for ease of use;

Weighing: Weigh the materials of components A and B according to the weight ratio specified in the technical specifications;

Mixing: Component A contains functional fillers, which may precipitate after long-term storage. Therefore, it is necessary to open the packaging bucket and mix thoroughly before use;

Mixing: Pour the weighed components A and B into a mixing container, and stir vertically with a stirring rod. Stir in the same direction (clockwise or counterclockwise) for 3-5 minutes, minimizing the intake of air. Pay attention to stirring evenly at the bottom and edges of the container, otherwise there may be local non solidification;

Defoaming: If the sealing surface is required to be smooth and free of bubbles, the mixture should be vacuumed at -0.1Mpa to smoothly remove the bubbles;

Pouring: Pour the mixture into the device. If the device structure is complex or the volume is large, it should be poured in batches. The pouring bubbles can be blown with a hot air gun to eliminate surface bubbles;

Curing: It can be cured at 48-72H/25 ℃ or 3-4H/60 ℃. If the temperature is low, the curing time should be extended as appropriate. This product is sensitive to moisture, which can cause curing bubbles. It is recommended to control the operating environment at 25 ℃± 3 ℃/relative humidity<60%.

Equipment sealing operation process: dedicated glue filling machine

Preheating: When the material is below 25 ℃, the product should be placed in the aging room for preheating in advance to ensure that the temperature of the product is not lower than 25 ℃, in order to avoid high viscosity and inconvenient material extraction;

Material extraction: Component A and component B are separately extracted into the corresponding material tanks. During the extraction process, attention should be paid to observing the generation of bubbles. When the bubbles reach the top, they should be released in a timely manner to prevent them from being sucked into the vacuum system;

Heating: It is generally recommended to control the temperature between 40 ℃ -60 ℃ to reduce the viscosity of the material, which is beneficial for flow rate and vacuum degassing effect;

Degassing: When the material temperature rises to 40 ℃ -60 ℃, start vacuuming and degassing. It is recommended that the general vacuuming time be 30-60 minutes;

Filling: Adjust the flow rate, take multiple samples before filling, calculate the correct ratio separately, and start filling after confirmation;

Curing: It can be cured at 48-72H/25 ℃ or 3-4H/60 ℃. If the temperature is low, the curing time should be extended as appropriate. This product is sensitive to moisture, which can cause curing bubbles. It is recommended to control the operating environment at 25 ℃± 3 ℃/relative humidity<60%.

precautions

1. AB component raw materials need to be used with specialized equipment and mixed evenly according to the specified usage ratio. The components should be dry and free of water vapor. If there are bubbles, they need to be evacuated.

2. After adjusting the AB component raw materials, try to use them up within the operable time, otherwise they will solidify and cannot be used again.

3. This product is sensitive to moisture, please use it as soon as possible after opening the packaging.

4. Each model of product has a different modulation ratio and cannot be mixed with other models at will.

Scope of use:

Mainly used for indoor electrical components with low heat generation, it can prevent the installed and debugged electronic components and circuits from being affected by vibration, corrosion, moisture, dust, etc.

Such as communication equipment, transformers, control power supplies, ignition controllers, electronic sensors, LEDs, etc.

Packaging specifications: 25KG/drum for component A, 5KG/drum for component B