Electronic adhesive silicone: the 'invisible guardian' of high reliability electronic devices

In modern electronic manufacturing, electronic adhesive silicone has become the core material for ensuring equipment stability. This special adhesive, with its unique properties, provides comprehensive protection and support for electronic components, becoming an indispensable "invisible guardian" in high-end electronic devices.

1、 Core Function Analysis

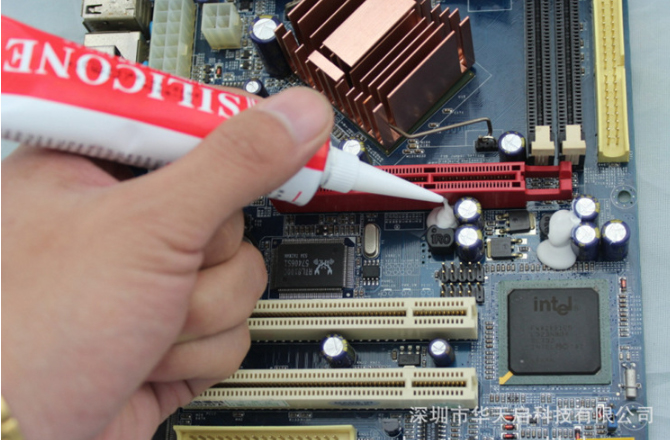

High strength bonding and fixation

Electronic bonding silicone can firmly bond metals, ceramics, glass, and various plastics (such as ABS, PC, PET), effectively preventing components from falling off or shifting during vibration, impact, or transportation. For example, key components such as capacitors, transformers, and inductors on the power PCB can be fixed with silicone, which can increase their seismic resistance by more than 50%.

Efficient heat conduction and dissipation

To address the issue of heat generation in power devices such as IGBT and MOSFET, thermal conductive silicone (with a thermal conductivity of 1.2-2.5W/m · K) can fill the gaps between the components and the heat sink, significantly reducing the operating temperature. Experiments have shown that using thermal conductive silicone can reduce the temperature of power devices by 15-30%, significantly extending their service life.

Insulation and sealing protection

Electrical insulation: The volume resistivity can reach up to 10 ¹⁴ -10 ¹⁷Ω· cm, effectively preventing arc breakdown in high-voltage environments (dielectric strength 18-23kV/mm).

Three proof capability: Form a waterproof, moisture-proof, and chemical corrosion-resistant sealing layer to protect the circuit board from stable operation in harsh environments such as humidity and salt spray.

Stress buffering and shock absorption

After solidification, an elastic body (Shore A hardness 30-67) is formed to absorb mechanical stress during equipment operation and prevent brittle components from cracking due to thermal expansion and contraction.

2、 Six irreplaceable advantages

Extreme temperature adaptability

The working temperature range is -60 ℃ to 280 ℃, and the instantaneous temperature resistance can reach 310 ℃ (such as TG-918R model), far exceeding traditional adhesives such as epoxy resin. It is suitable for high temperature scenarios such as automotive engine control modules and industrial frequency converters.

Environmental Protection and Safety Certification

Through RoHS, REACH, UL94 V-0 flame retardant standards, it does not contain organotin and heavy metals, has low VOC emissions, and meets the safety requirements of high-end fields such as automotive electronics and medical equipment.

Convenience of craftsmanship

Single component de alcoholization/de ketoxime type design, room temperature curing (surface drying for 10-60 minutes), no need for mixing or heating equipment, greatly improving production efficiency.

Long term stability

Resistant to UV and ozone aging, with a performance degradation rate of less than 5% after more than 10 years of outdoor use, ensuring long-term reliability of photovoltaic inverters, communication base stations, and other equipment.

Wide material compatibility

It is non corrosive to metals such as copper and aluminum, and has a low molecular weight siloxane content (<300ppm) to avoid contaminating precision circuits.

Comprehensive cost optimization

Reduce the use of mechanical fasteners, simplify the assembly process, reduce the failure repair rate by 40%, and significantly reduce manufacturing costs.

3、 Precautions for use

Surface treatment: The substrate needs to be cleaned and dried, as oil residue can cause a decrease in adhesion of more than 30%.

Curing control: For adhesive layers with a depth greater than 2mm, the curing time should be extended (recommended 72 hours), and spraying water mist when the humidity is less than 40% can accelerate the reaction.

Storage conditions: It must be sealed and stored in a cool environment at -10~25 ℃ to avoid curing failure.