It is specialized in transparent packaging protection of outdoor LED lamps and other electronic industries, and belongs to silicone elastic electronic component potting adhesive.

Product introduction:

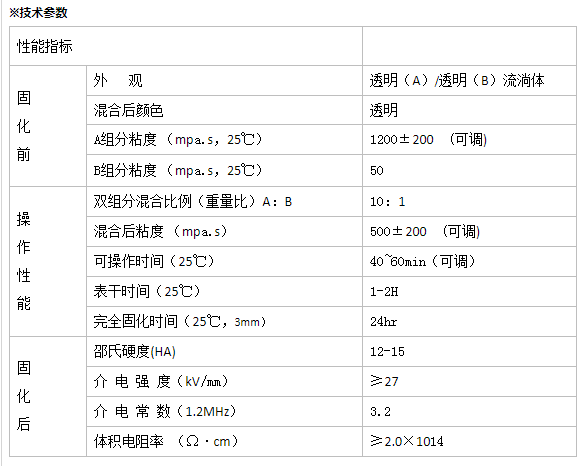

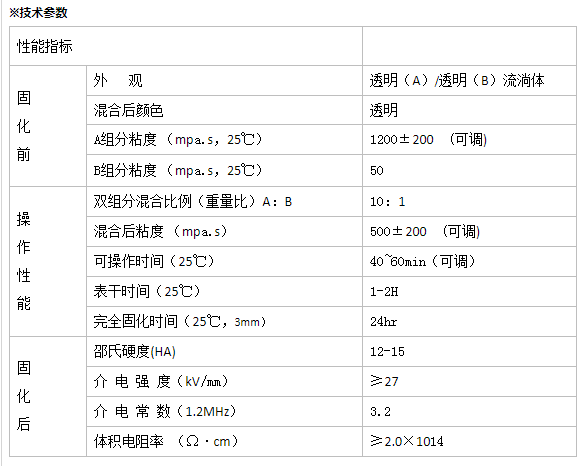

Cs-9809c silicone potting adhesive is a transparent two-component compound, which is composed of a and B liquid. When the two components are fully mixed with a weight ratio of 10:1, they can be filled and sealed. The mixed liquid will be solidified into a flexible high insulation elastomer at room temperature, and there is no obvious shrinkage and temperature rise of the material during curing. This product is suitable for the packaging and protection of electrical / electronic products.

This product will not corrode metal and electronic components. The material is nontoxic, completely solidified after insulation, moisture proof, vibration proof, mildew proof, acid and alkali resistant, UV resistant and anti-aging. It can withstand high and low temperature (-50 to 250 degrees can work steadily for a long time). It has good repairability and excellent weather resistance. It is specialized in transparent packaging protection of outdoor LED lamps and other electronic industries, and belongs to silicone elastic electronic component potting adhesive.

Usage and precautions:

1. Glue the ratio of a: B = 10:1;

2. Stir for 3-5 minutes. The agitator shall be placed at the slightly deviated position of the liquid level center, and the depth of the agitator inserted into the glue is 1 / 2-2 / 3 of the glue liquid height, which is the best (based on the height from the liquid level);

3. If the glue filling machine is used to fill the module, the proportion of a glue to B should be set first, small amount of test should be carried out, and the first use should be made. At the same time, the electronic scale should be used to accurately mix the glue according to 10:1, so that the results of the machine test and the manual test can be compared. If the results of the machine test and the manual electronic scale test are the same, it means that the glue output of the machine is also according to a: B = 10:1, so that It can be seen that the amount of B glue used by the machine is more or less, which is convenient to control.

4. It can be filled and sealed after mixing evenly, but the mixed glue must be filled within the operable time (i.e. before the surface dry time).

5. There is no need to defoaming before pouring, and the curing process will self defoaming, but the curing agent B must not exceed the standard, so as to ensure that the surface drying time of the mixed solution is within the range of 28-50 minutes.

Special reminder

&1. This glue cannot be mixed with other glue;

&2. The mixture of the two components should be as uniform as possible;

&3. If the conditions permit, the mixed glue should be treated as far as possible;

&4. The prepared glue must be used up within the operable time to avoid unnecessary waste;

5, when used as a surface drop, it is recommended that customers can drop the gel after the first time, then reconfigure the gel for second times until the gel is cured, and the appearance will be better after curing.

&Nbsp; & nbsp; & nbsp; 6. As a result, the series of glue will react when encountering water, and the unused glue must be sealed. The best storage condition is room temperature and shade.

&7. This product should avoid long-term contact with washing water, organic solvent such as Tianna water and strong acid and alkali.

&8. Since the materials and processes used by different customers are beyond our company's control, we must carry out matching test and sample before using the glue. After the sample is qualified, we can use it safely.

Product features

1. No corrosion: This product belongs to dealcoholization reaction and will not corrode metal and LED devices

2. Rapid curing: the operation time is adjustable from 0.5 to 1.5 HuR, and the 2 to 4 HuR can not flow vertically, so the efficiency is improved;

3. Good fluidity: it can self level quickly and use automatic glue filling equipment;

4. Good adhesion: the solidified product has good adhesion to the module shell (metal, plastic, etc.) and led;

5. It has excellent high and low temperature resistance (- 55-220 ℃) and excellent electrical insulation performance;

6. Good flexibility;

7. Excellent moisture-proof performance, the product has structural self hydrophobic performance, overall hydrophobic;

8. Excellent weather resistance: UV resistance and atmospheric aging resistance;

9. It is transparent after complete curing;

10. Repairable: the sealed components can be taken out for repair and replacement, and then repaired with this potting glue.

Official website of mobile phone

Official website of mobile phone WeChat public address

WeChat public address